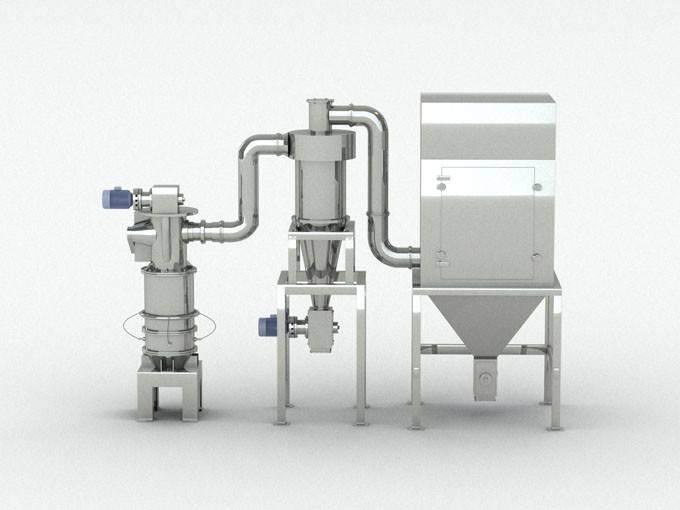

30B series universal crusher

This crushing unit consists of crusher, ESC material collection box and ESC vacuum cleaner. Solve the dust flying of the material during the crushing process. The working principle of this machine is that the material enters the crushing chamber, and is crushed under the action of the impact, shearing, friction and mutual impact of the teeth between the high-speed rotating movable toothed disc and the fixed toothed disc, and after being screened by the screen, it will be crushed. into the desired powder.

model | 20B | 30B | 40B | 60B |

Production capacity (kg / h) | 60-150 | 100-300 | 160-800 | 500-1500 |

Spindle rotation speed (r/min) | 4500 | 3800 | 3400 | 2800 |

Feed particle size (mm) | 6 | 10 | 12 | 15 |

Finished product fineness (item) | 60-120 | 60-120 | 60-120 | 60-120 |

power of motor (kw) | 4 | 5.5 | 11 | 15 |

weight (kg) | 250 | 320 | 550 | 680 |

Overall dimension (length, width and height) (mm) | 350×600×1250 | 600×700×1450 | 800×900×1550 | 1000×900×1680 |

The crusher, material collection box and vacuum cleaner of this crushing unit are all made of stainless steel. Meet the requirements of GMP for pharmaceutical production.

It can handle the crushing of various materials such as chemicals, food, medicine, cosmetics, dyes, resins, shells, etc.

The machine is designed according to the "GMP" standard, and the whole machine is made of 304 stainless steel.

After repeated tests by the environmental protection department, the amount of dust discharged and prevented is much lower than the dust emission standard stipulated by the national environmental protection department. The entire production process is automatically controlled by the control cabinet. The control cabinet supplies the entire production motor (excluding the gas source and electricity), and can also control parameter adjustment, automatic start and stop, automatic protection, fault alarm and automatic shutdown. Ensure the safe operation of equipment and the stability of product quality.